S.H.I.E.L.D. stands for Safeguarding Healthcare Individuals & Essential Laborers Daily.

The S.H.I.E.L.D. project was started by the founders of Asprodental electronic health record software. While attempting to help their clients and partners procure PPE, they faced the reality of the national supplies shortage. The Asprodental team has partnered with PacMin, an aerospace model creation company, to bring these disposable face shields to local healthcare facilities.

Many big corporations are already making ppe, why do we need more?

It’s fantastic that we’re all pulling together to alleviate the PPE shortage! While production is increasing, certain factors are still causing the shortage to continue.

The biggest factor is demand. Drastic increases in medical operations are far surpassing the production capabilities of usual PPE manufacturers. Even with the new production efforts from companies that normally make clothing, electronics, etc., we are still playing catch up.

One of the hardest hit groups are smaller local healthcare facilities – think your neighborhood urgent care or family-owned dental practice – who don’t have the procurement resources that larger hospital systems do (who are also experiencing shortages).

The most undeniable evidence is in our email inbox. Our biggest motivation behind S.H.I.E.L.D. is the requests that we have been receiving from both hospitals and local clinics who are asking if we can help get them face shields.

Why face shields?

Face shields are adjunctive PPE (personal protective equipment) worn in addition to masks and other protective equipment. The shields protect healthcare workers from sprays and splatters, such as those produced as a result of AGPs (aerosol-generating procedures), or simply from patients' coughs.

Each face shield can be used by a frontline worker for an entire day, or by a general worker for several days with proper sanitization.

How are we producing the shields?

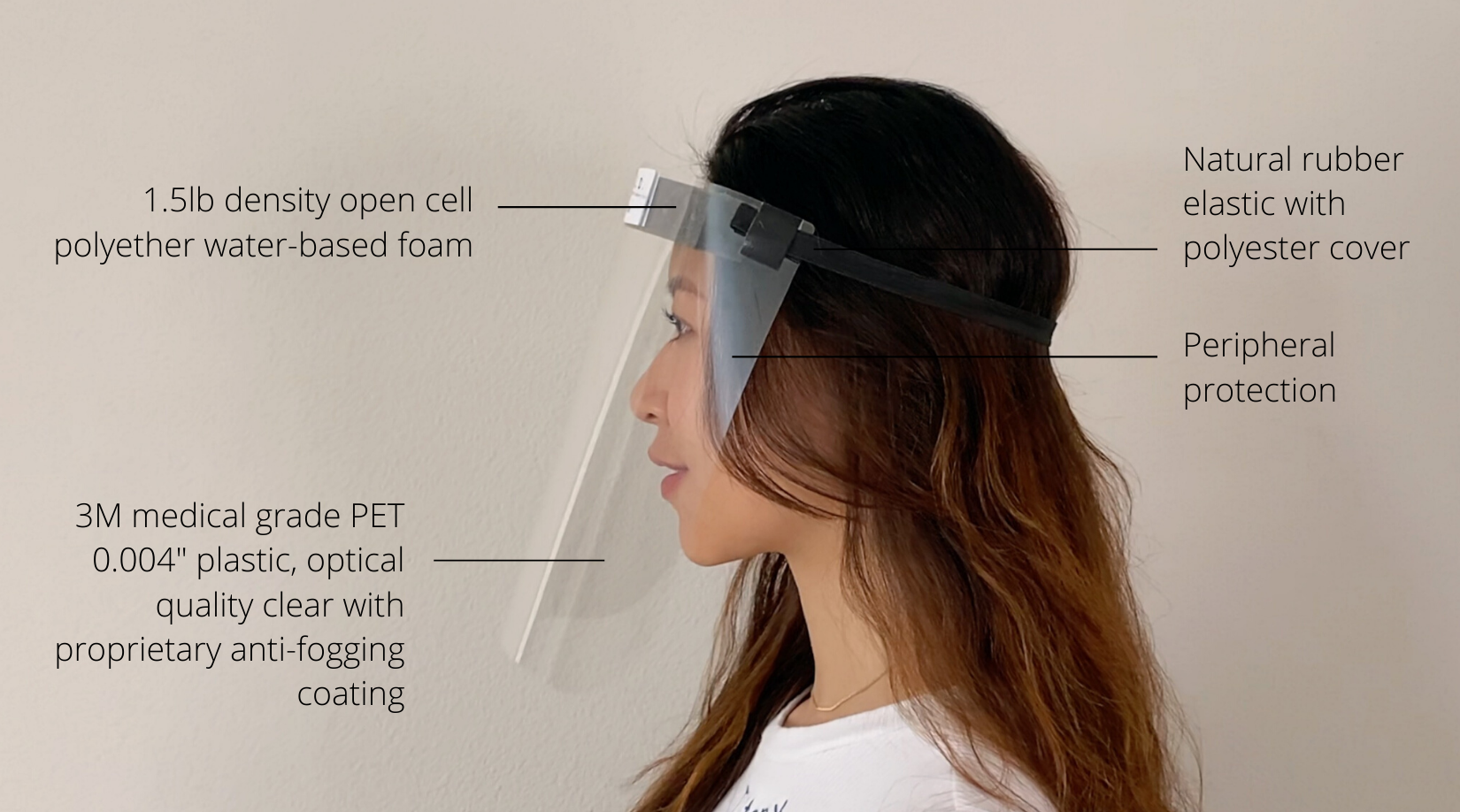

Face shield visors are made of 3M medical grade plastic with anti-fogging coating to keep the wearer’s vision clear and unobscured. Each face shield is outfitted with a water-based foam forehead cushion and elastic strap. The flexible visor sheet and foam cushion form to the wearer’s head to create a peripheral barrier that extends past the temples.

The shields are assembled in PacMin’s facilities in Fullerton, California. Our assembly workers are a combination of volunteers and PacMin staff who normally work on making aerospace models.

$4 = 1 fACE SHIELD

Raw materials and assembly labor are being supplied at cost, and both Asprodental and PacMin are facilitating the project without compensation. That means your contribution will go directly toward face shields, with no mark-ups.

Who will receive these face shields?

Simply put, anyone who needs them. Many facilities, from hospitals to local clinics to prosthetics manufacturers, have already been asking us for donations. Initially, these facilities heard of the S.H.I.E.L.D. project through Asprodental and PacMin’s professional networks. Asprodental is a longtime supporter of free medical/dental clinics and PacMin is involved with Rotary International community projects. As word spread, we began to receive requests from facilities who heard about us from their colleagues, who heard about it from their colleagues, and so on.

To request face shield donations, please contact us with information about your facility and provide your mailing address. We will try to donate as many shields as to each facility as possible from the funds raised on our donation page.

We also have face shields available to order directly if you need them for your own facility. Our production time is currently 10-14 days.